Dam / Tunnel / Generating Station

The Dam

Work began on August 10, 1926, with three phases of construction, leading to the hiring of 1,000 men to work at the dam, supply tunnel and the power plant itself.

The dam has 11 barriers, two 20 feet (6m) and nine 48 feet (14.5m). The gates are flush with the ground, so that when the barriers are opened, there is a full discharge.

The two small barriers are operated by a fixed crane. The larger barriers are operated by two movable cranes and can be fixed in the open position using a pin.

The intake valve is of the Johnson-Walham type and consists of two horizontal tubes of 200 feet (60 m) each, placed parallel to the river and ending in a Y, which in turn flows into the main tunnel. There is a lamella along the full-length of each tube, wider at the entrance and narrower near the Y. Between each tube and the Y, there is an electric butterfly valve and between the valves and the Y, there are aerations tubes. There are debris traps 16 feet (nearly 5 m) deep in front of the intake valve.

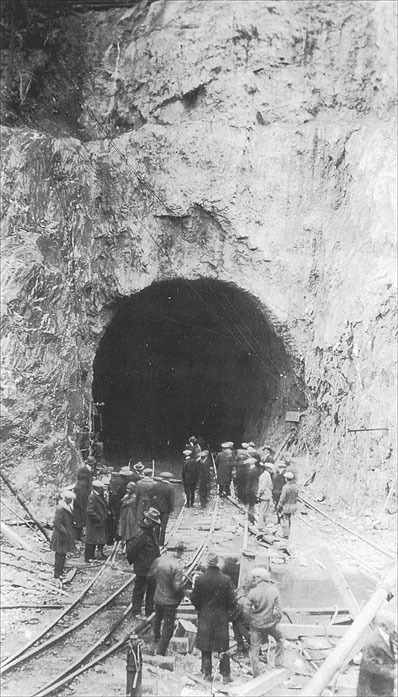

The Tunnel

The tunnel is lined with concrete and has a diameter of 26 feet (nearly 8 m), it is horseshoe-shaped with a V-shaped bottom.

The concrete gravel originated on Sharp Island near Woodstock and was transported by locomotive by the Canadian Pacific Railway. Suitable gravel could not be found any closer.

Construction of the tunnel began at both ends. Houses to house the compressors were built at each end.

It is half a mile (about 805 m) long and passes to a depth of 200 feet (60 m) below the town center.

It is located on a curvature in the river, so the tunnel cuts directly through the curvature. There is a sudden rise tank at the lower end of the tunnel and the differential type with bulkheads inside to lessen the effect of sudden rises of water. Without the water load, the tank is filled to 1/3 of its capacity, but with a full load the water it just reaches the upper part of the bell, and with the full load rejection, the tank would almost fill.

Beyond the sudden rise tank, the tunnel divides into two penstocks and these in turn divide into two other pipes. In each of these pipes, there is a 12-foot (4 m) hydraulically operated butterfly valve.

Once completed, the Grand Falls tunnel became the largest of its kind in Canada.

The Generating Station

The 550 V auxiliary generator drives the motor-generator which excites the main generator. It was believed that this somewhat complicated excitation system was necessary to control the transmission line from Grand Falls to Dalhousie, one of the longest on the continent when it was built. After being turned on, it was discovered that this system was not needed, so the last unit was installed with a much simpler system.

The generators produce an efficiency voltage of 6,900 volts. Two of them supply the 69,000-volt line, and the other two the 138,000-volt line.

Electrical power during the construction was provided by Maine and New Brunswick Power's hydroelectric generating station at Tinker (near Aroostook, NB).

At NB Power, they are seriously concerned about public safety around hydroelectric plants.

Warning horns downstream of the Grand Falls generating station were installed to warn the public when there will be a major water spill.

When there is a water spill of more than 1,000 cubic feet per second at the plant, horns will sound to allow anyone downstream of the plant to take the necessary precautions.

source : Histoire de Grand-Sault / Grand Falls Yesterdays - Margaret Marceau